The boiler house was an important element of the old Royal Adelaide Hospital, without it, the hospital would not have fully functioned.

Initially, the boiler house purpose was to provide steam and hot water to the laundry and kitchen, as well as providing steam to the hospital buildings. For this reason, the laundry and kitchen were co-located close to the source of steam. This was to reduce the loss of heat due to the distance it had to travel in the steam pipes.

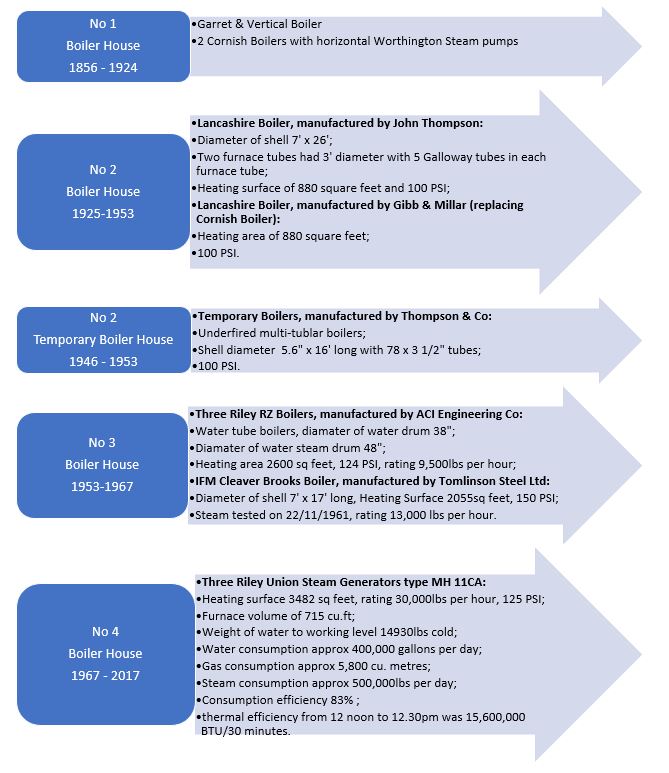

No 1 Boiler House – 1856 to 1924

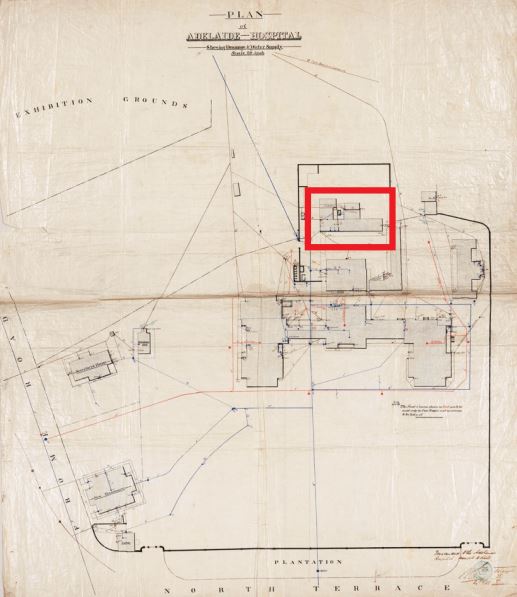

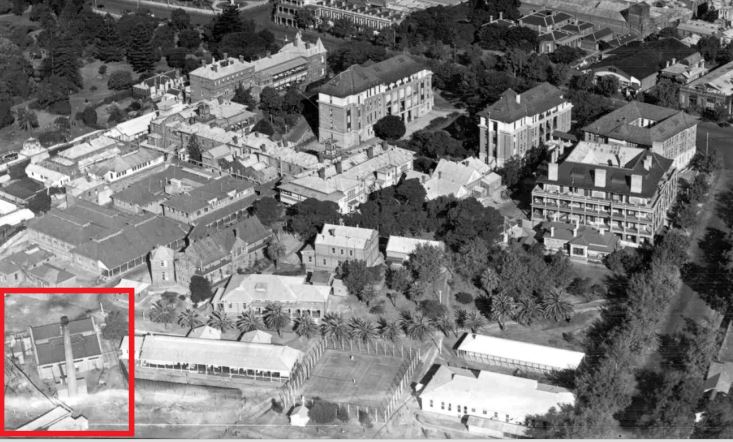

The first boiler house on the North Terrace site was located between the kitchen and laundry (west of the old Casualty Building [Terrace Ward] and north of the main Hospital buildings). It is not really clear when the first boiler house was completed and began operations. It is presumed that the boiler house was operational by the time the hospital opened in 1856.

Constructed of wood and galvanised iron, the original boiler layout was for two boilers, likely one was a standby in case of failure or when a boiler needed maintenance. The boiler room and chimney originally had a small footprint and a medium height chimney. While small, the boiler house and its chimney were integral part of the overall hospital.

One of the steam boilers installed was a Garret and the other an unknown vertical boiler. Invented by British Engineer Herbert William Garratt (1864-1913), Garratt steam boilers were typically used on steam locomotives, where more power was needed.

Coal was used as the main fuel source for the Adelaide Hospital boilers.

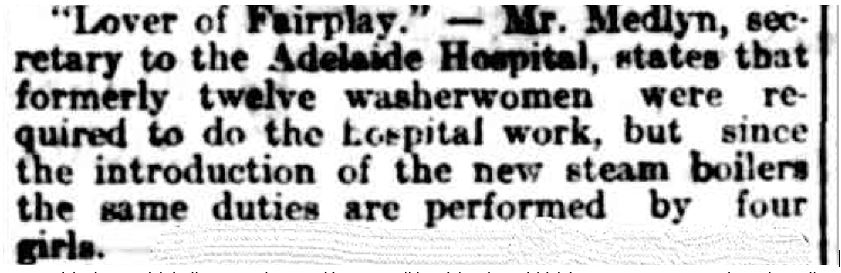

At the beginning of the twentieth century, the original boilers were removed and replaced with two small Cornish boilers with horizontal Worthington steam pumps. These pumps greatly increased steam output.

Unsurprisingly, Cornish boilers were invented in Cornwall by Richard Trevithick in 1803. Known as a Fire Tube Boiler, its shape was horizontal, cylindrical, with a single furnace tube running from the front to the back. These boilers were hand fired and needed a fireman/engineer in constant attendance to maintain the fire. This ensured an even supply of steam at the correct pressure.

The introduction of Worthington steam pumps (invented in 1885 by Henry R Worthington) reduced the number of people who needed to work on the hospital boilers. Worthington steam pumps automatically sent water to the boilers, whereas prior to this, boiler feed water pumps were operated manually.

The two vertical Worthington steam pumps saw service for nearly fifty-four years, before being taken out of service and transferred to the Parkside Mental Hospital Boiler House in 1954.

The Cornish boilers were coal fired.

Early Adelaide Hospital Firemen/Engineers (1891-1918)

To perform their role, the Adelaide Hospital fireman/engineer needed to know:

- all the safety aspects of the boilers operation;

- a knowledge of the different firing methods;

- the importance of cleaning the ash pit regularly;

- how to clean a fire of clinker and coarse ash; and

- the most important duty was to make sure there was adequate water supply, as shortness of water was fatal to any boiler.

Firemen (Not Complete):

- 1891: William Murphy. Transferred from Assistant Cook to Fireman in May 1891. He resigned July 1895;

- 1895: Thomas Passmore, Fireman. Started July 1895 and died January 1899;

- 1899: John Howard, Fireman. Started February 1899 on 30 shillings per week;

- 1901: William Hammett. Promoted from Porter to Fireman in November 1901. Retrenched 1903;

- 1903: John Grieve, Fireman. Started February 1903 and resigned four months later in June 1903;

- 1903: Jno Martin Williams, Fireman. Started June 1903 and resigned November 1906;

- 1905: John Davies, Assistant Fireman. Started July 1905 and resigned September 1907;

- 1906: Alfred Earnest Gillard, Fireman. Started December 1906 and transferred to the Old Folks Home August 1916;

- 1907: Samuel Henry Horne, Engineer. Started July 1907. He had a salary increase in July 1907 to 65 shillings per week and a further increase to 73 shillings and 6 pence in July 1916;

- 1916: George Wilks, Engineer. Started August 196 and resigned February 1918; and

- 1918: Alfred Ernest Gillard, Engineer. Reappointed April 1918 on 73 pounds per year.

No 2 Boiler House – 1925 to 1953

Construction on a new complex including boiler house, kitchens, laundries and storage rooms began in 1923. A new boiler house was necessity as there had been many complaints over the years about the boiler house, in particular the chimney.

Last Monday large quantities of soot were falling all day outside – and consequently, nearly all the nurses’ clothes became very grimy when hung out to dry. I had most of them washed again on the following day, but the soot still came down heavily, and so the clothes were returned at the end of the week in a somewhat unsatisfactory condition.

Fortnightly report from Eleanor G Laurence (Laundry Forewoman) to Adelaide Hospital Board of Management, 29 April 1912

“The boiler block would form the nucleus of very extensive alternations which had been planned. Most careful consideration had been given to the requirements of the institution, not only for the present but for a considerable time to come … the whole scheme, when completed, would enable the hospital to cope with the ever-increasing demands made upon its space and its resources with the growing needs of the State” .

The Register, 27 April 1923

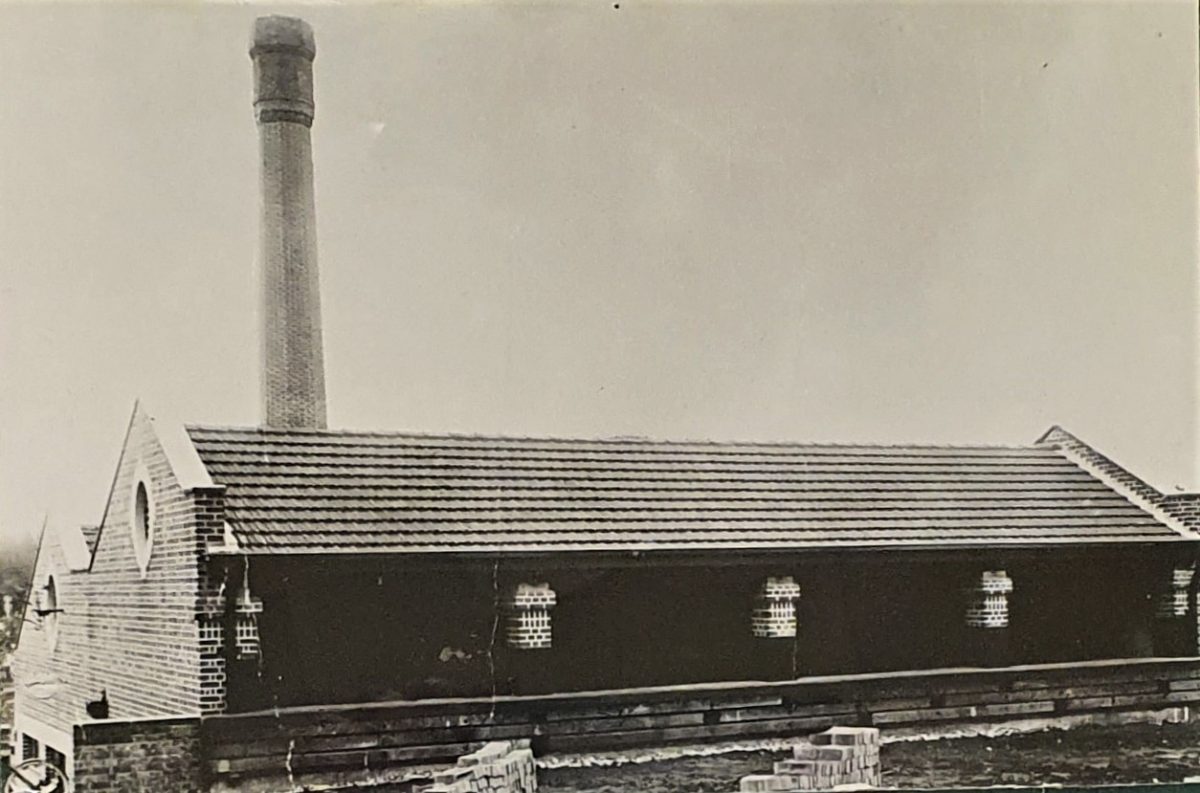

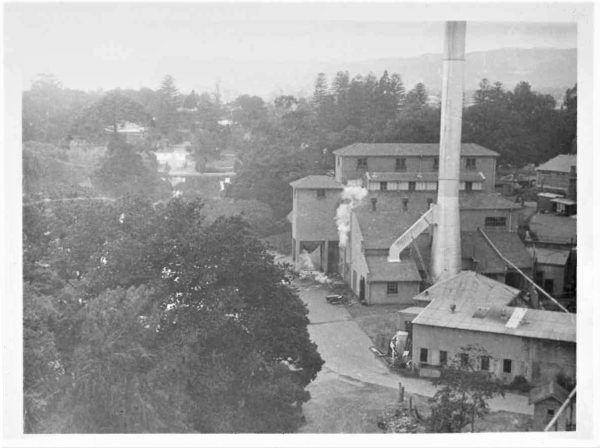

The new red brick building was situated North-West of the original boiler house and alongside Torrens Ward (later changed to Frome Ward). The coal bunkers were on the Eastern side at ground level. The boiler house and laundry block were completed by 1925, but work on the kitchen and stores block were postponed and finally completed in 1926.

The new boiler house (known as Boiler House No 2) had two boilers (see end of history for operating statistics):

- Lancashire Boiler manufactured by John Thompson in 1925. This boiler had 28 years of service at the Adelaide Hospital before being taken out of service October 1953 and transferred to Myponga Cooperative Dairying Society in 1957.

- Cornish Boiler manufactured by Perry Engineering Co in 1916 and transferred from No1 Boiler House. This was taken out of service in 1938 and the boiler was replaced by a Lancashire Boiler manufactured by Gibb & Millar for 1650 pounds in 1939.

During this period, the Adelaide hospital expanded significantly, with the construction of several new wards and buildings. To accommodate the expansion, a new underground tunnel, at least 600 feet long was built

large enough for a man upright to walk through. It is part of a scheme under which big extensions will be made to the hospital’s steam supply system. Steam drawn through pipes from the boiler-house at the rear of the property will be used for heating purposes in the wards, including sterilising, steam kettles, cooking and washing.

News, 17 February 1934

War Years:

During the Second World War, coal throughout Australia was in high demand. Breakdowns at the Boiler House, including unsatisfactory supply of steam to the hospital, were frequent during this time. This was due to the supply of inferior coal.

The Acting Lay Superintendent reported that much delay and inconvenience of a serious nature was being experienced throughout the hospital because of a lack of steam. The laundry was seriously delayed in its output and sterilizers in theatres and wards were defective; in one theatre it took one and a half hours to boil a sterilizer prior to an operation at 9.00am.

Royal Adelaide Hospital Board Minutes, 21 August 1946

Leigh Creek produced quantities of coal but of inferior quality – where possible the hospital used Newcastle coal and up to 4,000 tons a year. A temporary Boiler House of wood and galvanised iron was built next to No 2 Boiler House stack. This was designed to use Leigh Creek coal, with over 200 tons a week consumed. The boiler was manufactured by Thompson & Co. in Victoria (1921) and installed at Cadell (River Murray) for Department of Lands.

No 3 Boiler House – 1953 to 1967

By 1953, the boilers were becoming old and obsolete and conditions within the Boiler House were dusty and dirty. In an effort to alleviate dust, the coal was sprayed with fuel oil, which didn’t improve working conditions.

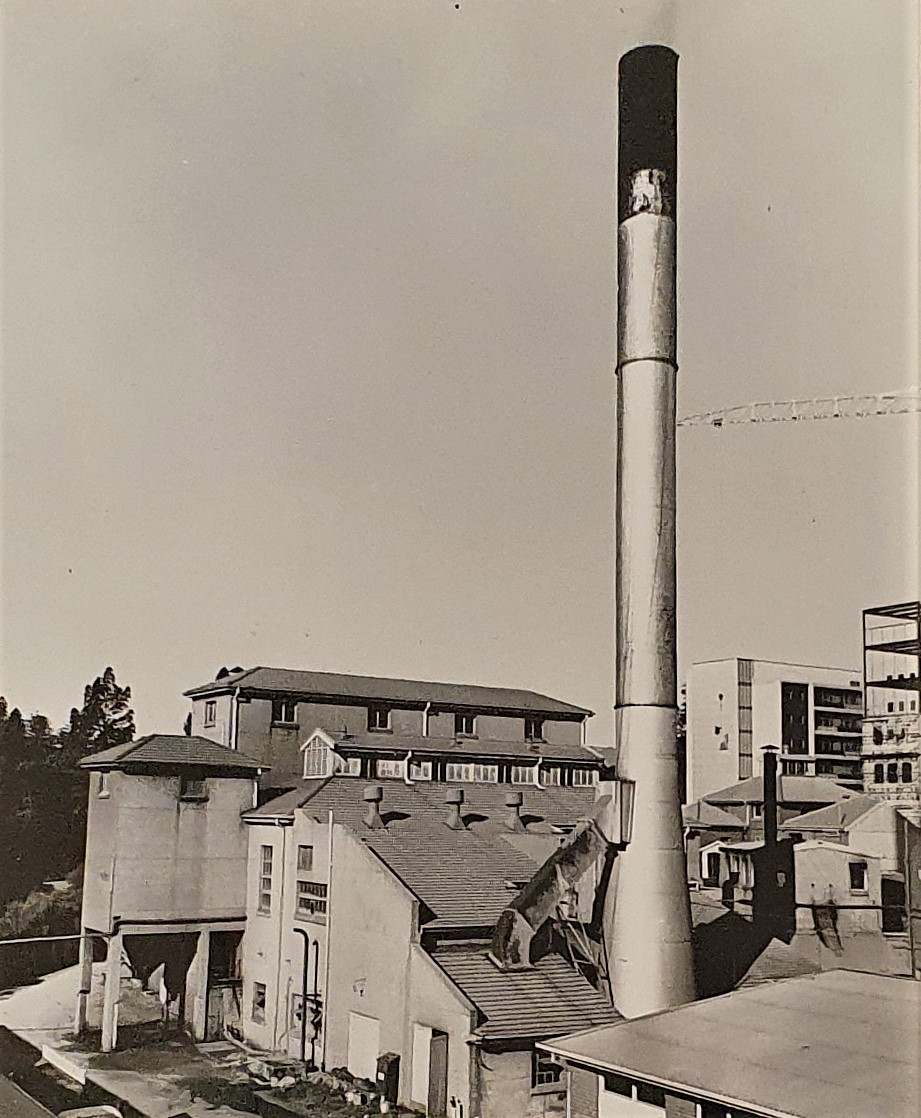

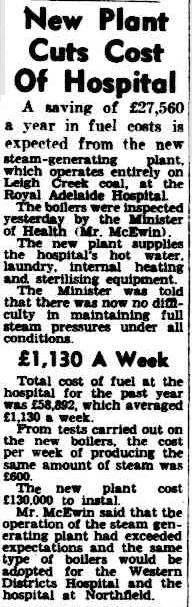

A new steel and concrete building, costing 130,000 pounds was built just North of No 2 Boiler House. Three Riley RZ type boilers, manufactured by ACI Engineering Co were transferred to Royal Adelaide Hospital. The boilers were steam tested on 9 September 1953 and operational by 14 September 1953. They were installed with two vertical Weir steam pumps.

These were coal fired.

An additional Boiler House was added in 1962. Built of steel and galvanised iron, it was situated on the Eastern end of No 3 Boiler House. A Cleaver Brooks Boiler manufactured by Tomlinson Steel Ltd in 1960 was installed. This boiler was oil fired.

No 3 Boiler House closed down, June 1967.

No 4 Boiler House – 1967 – 2017

During the 1960s, the Royal Adelaide Hospital undertook a large redevelopment of the whole site, with the majority of the old buildings being demolished. As part of this process a new Boiler House was constructed. Located due west of the No 3 boiler house, it was situated on the northern perimeter of the hospital adjacent to the Frome Road entrance.

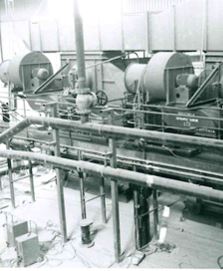

The steel and concrete building held three Riley-Union Steam Generators and four vertical Weir Steam pumps. These were oil and gas fired. In summer, 2 boilers were on line, while one boiler was on standby. In the winter, three boilers were on line, depending on the demand.

The building was two storeys, including a basement. Locker rooms, staff amenities with minor storage space and some pumps were in the basement. This area was connected to the main service tunnels leading to the rest of the hospital.

The ground floor housed workshops for the different trades:

- Refrigeration & air-conditioning

- Plumbers shop

- Painter Shop

- Electricians

- Key cutters/signs

- Fitters shop

- Carpenters shop

- Offices

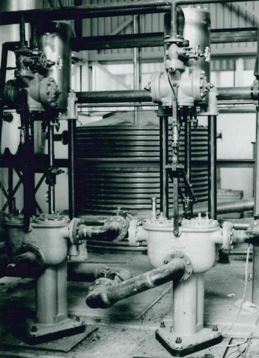

- Water Treatment Room/storage

The first floor was the boiler room which covered the whole of the complex at first floor level. It contained three gas fired boilers with oil firing option feeding from the oil tanks in the catacombs below. Two thirds of the space was taken up by water treatment. An electrical switchboard concerned with the pumping of water and with energy management was situated centrally. The boilers were attended 24 hours a day. There were central stairs from the main ground floor corridor and another set of stairs on the Eastern side which lead to the water treatment room.

The boiler house flue was 45 metres high.

Demolition

After fifty years of service, the No 4 boiler house was no longer needed after the hospital moved sites to Port Road. In 2021, the boiler house was demolished. Because of the many structural challenges, a staged approach was needed to dismantle the boiler house. The flue alone, standing at 45 meters tall, was taller than the excavators reach – 40 metres at its maximum. A crane was brought in and the top 5 metres of the flue were manually demolished with jackhammers before the rest of the flue was pulled down with the excavator.

Boiler Operating Statistics

Written by Margot Way, CALHN Health Museum